Our company owns new advance level technology of composite chlorine gas cooling tower, packing drying towerbubble combination dnying tower and demister combination device. Our technology has applied in successfuly in chlorinegas drying system of domestic chlor-alkali enterprise. Our equipment has the advantage of reliable operation, low energyconsumption. Water content of liquid chlorine reaches a stable level about 50ppm.

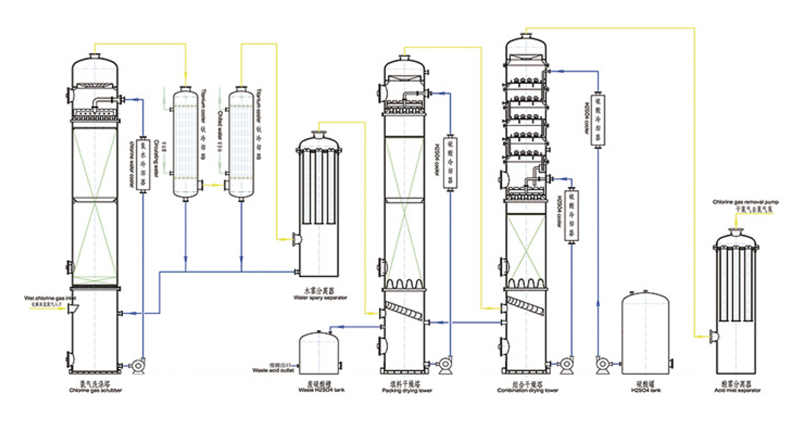

Process introduction:

The diferent pressure wet chlorine gas with 60'c~ 80'c from electrolytic cell passes through chlorine gas scrubber, fitaniumcooler, water spray separator, packing drying tower, combination drying tower. Then it willbecome dry chlorine gas. The drychlorine gas is pressured by turbine and transported into backsection for processing or use. When increasing the pressure byNash pump, it should be put behind of acid mist separator. 98%sulfuric acid is transported from tower top plate of combinationdrying tower by metric pump, it passes through tower platepacking section, packing drying tower successively. When theconcentration of sulfuric acid decreased into 70%~75%,it canbe discharged. Sulfuric acid in packing section of combinationdrying tower and packing drying tower should be circularlycooled by pump compulsively.Chlorine water separated fromtitanium cooler and water spray sepatator will return to chlorinegas scrubber. The chlorine gas will return to cleaning coolingtower after chlorine water from tower dechlorinated by heatexchanger.After it meets the discharging standard, it can bedischarged into gutter.

Technical features:

High drying efficiency: Water content of liquid chlorine is lessthan 150-400ppm after processed by single tower.While for multi-tower, the content is less than 25-100ppm.

Low pressure drop of the system: The max pressure drop can becontrolled within 500-800mm water column.

Good operating flexibility: Ratio of max and min load is 4.

Good mist removal effect: There is no mist on the outlet of demister basically.

Good anti-corrosion property: The main equipment is madefrom anticorrosion macromolecular composite material. Thewhole system has good anti-corrosion performance. The mainequipment does not need to be maintained within 10 years inprincipal.

Process flow diagram