Features:

High efficiency. Taking chlorine gas drying as an example, the water content of a single tower process can be reduced to ≤150~400ppm.

Large gas flux per unit area can make the tower cost more economical;

When the height of packing layer is 5m, the pressure drop of the whole tower is less than 100mm H2O.

Easy to operate, stable and reliable;

The whole tower is made of polymer material, the overall corrosion resistance;

The inner parts of the tower are manufactured with proprietary technology and have excellent performance.

The composite tower can be designed and manufactured into an integral structure even if the diameter is more than 2m.

The packing in the tower has various forms and good performance, all of which are made of corrosion-resistant polymer materials. Commonly used are: PP step ring, PVC, CPVC Taylor wreath and corrugated structured packing.

Inner parts:

Gas injection support plate:

The packing support plate bears the total load of the packing bed and maintains the free flow of gas and liquid. It is required to have large structural rigidity, strong bearing capacity and high opening rate. The liquid has good performance and three-dimensional structure. The porosity is not limited by the column section. The gas-liquid shunt passes through the support plate to avoid mutual entraining and reduce the pressure. The three-dimensional structure has large rigidity, strong bearing capacity, and can be designed to create a split detachable structure, which is easy to install and use. Material: hard PVC and high corrosion resistant FRP.

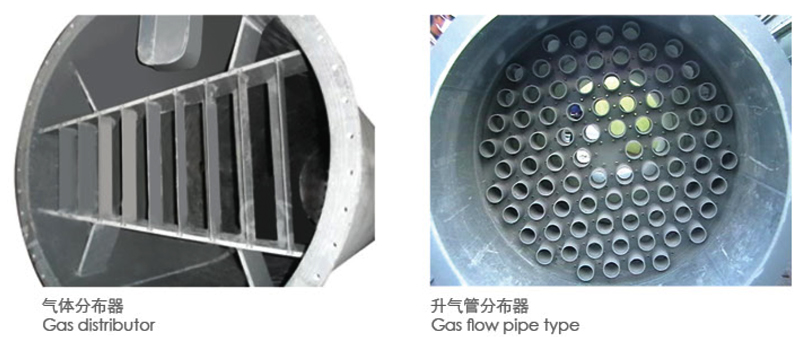

Interceptor baffle gas distributor:

With the development and use of large diameter packed tower, the conventional simple intake structure can not meet the requirements. At this time, it is necessary to add a gas distributor to improve the distribution of gas into the tower and improve the mass transfer efficiency. The gas distribution structure of the closure baffle is simple, and it is a good choice for the gas distributor of small and medium diameter tower.

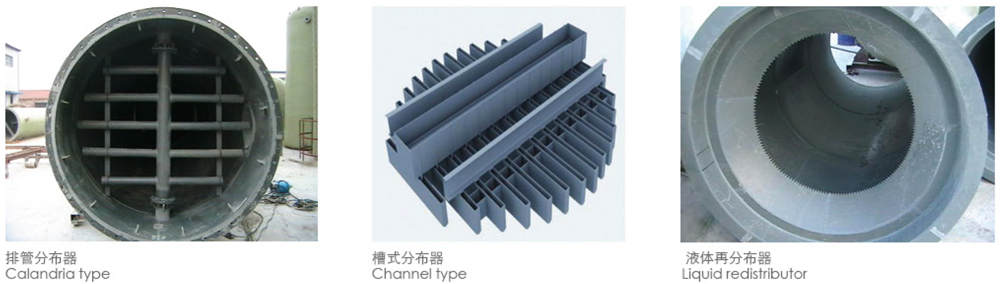

Liquid distributor:

In the packing tower, the design and manufacture of liquid distributor is very important. The liquid distributor designed and manufactured by Xingtai Company has good operation performance and uniform distribution. With suitable operating flexibility, there are enough airflow channels, single and compact structure.